インダストリー4.0とスマート・マニュファクチャリングの基盤

PDFソリューションズの製品は、オープンアーキテクチャー設計と業界標準を活用し、機器接続と制御ソフトウェアを提供します。弊社は、お客様の市場投入までの時間短縮と工場受入れを可能にする、実証済みの試験済みソリューション一式を提供します。

これらの製品は、マイクロソフト社のオペレーティングシステムと開発環境を使用して設計・構築され、接続性と制御性を最適化し、単一のプラットフォームで動作するように提供される一方、ソフトウェアエンジニアの大規模な人材プールを活用しています。当社のソフトウェア開発プロセスは、差別化要因であると同時に、すべての製品に共通するコアコンピタンスでもあります。当社の規律正しいテスト手順により、今日のスマート工場の厳しい信頼性要件を満たすことができます。

当社がサポートする主な業界標準

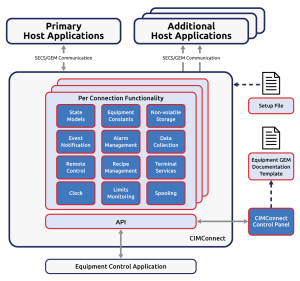

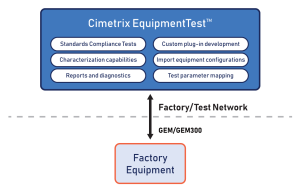

SECS/GEM規格: GEM(またはSECS/GEM)は、SEMI(Semiconductor Equipment Materials Initiative)によって開発された接続規格のグループです。これらの標準は、自動化装置とホストの工場ネットワーク間の通信を定義するために使用され、スマート・ファクトリー・マニュファクチャリングを可能にする。

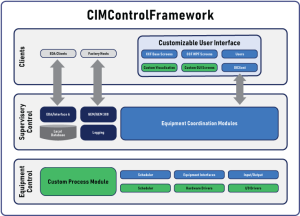

GEM300規格:300mmウェーハの導入は、はるかに大きな自動化を可能にするソリューションの要求をもたらしました。GEM300規格は、これらの課題を解決するためにSEMIによって開発されました。

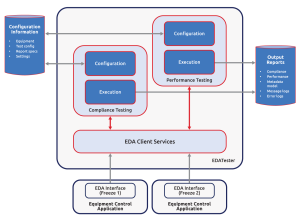

EDA/Interface A規格: Equipment Data Acquisition (EDA/Interface A)規格は、工場のデータ収集ソフトウェアアプリケーションと工場設備間の通信を容易にし、改善することを目的としたSEMI規格の集合体である。

PV2規格:効率を高め、統合コストを削減するため、太陽光発電(PV)製造コミュニティは業界標準の開発と実施を開始した。装置レベルでは、SECS/GEMをベースとした接続規格PV2がある。