How it Works

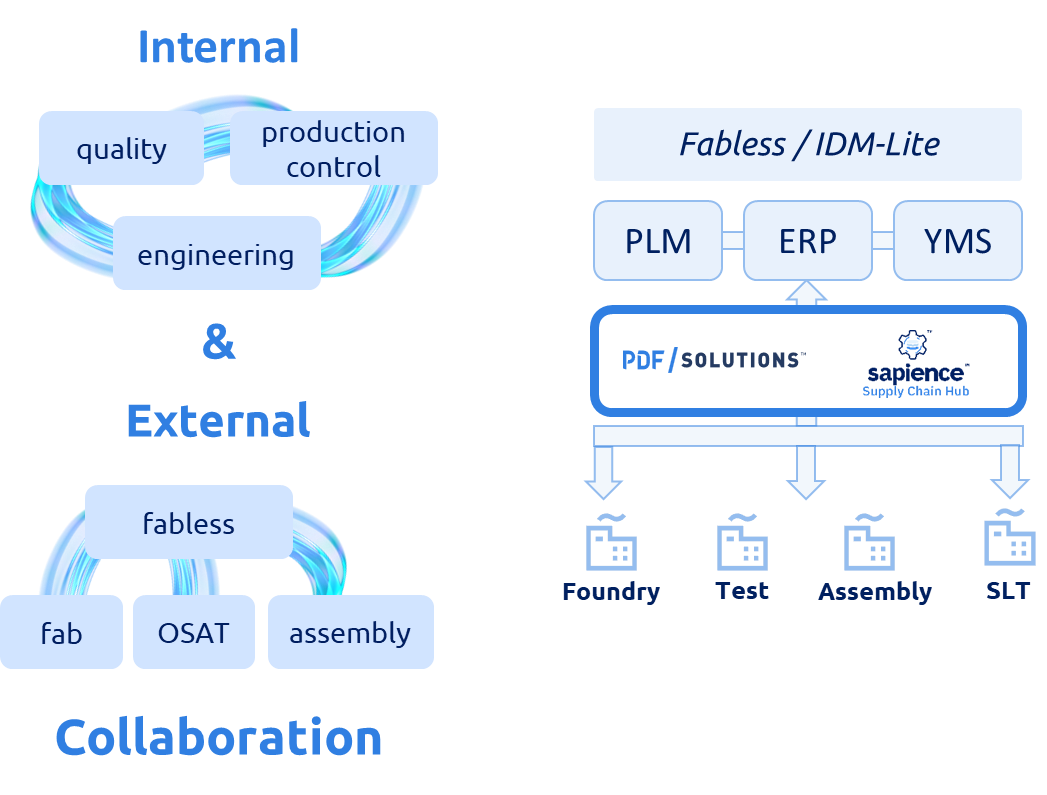

SCH orchestrates the end-to-end product lifecycle through a systematic, repeatable process. The platform centralizes control and visibility, functioning as the digital backbone for fabless manufacturing operations.

- System Integration & Data Ingestion: SCH sources BOM master data from your PLM and aligns work orders with your ERP system.

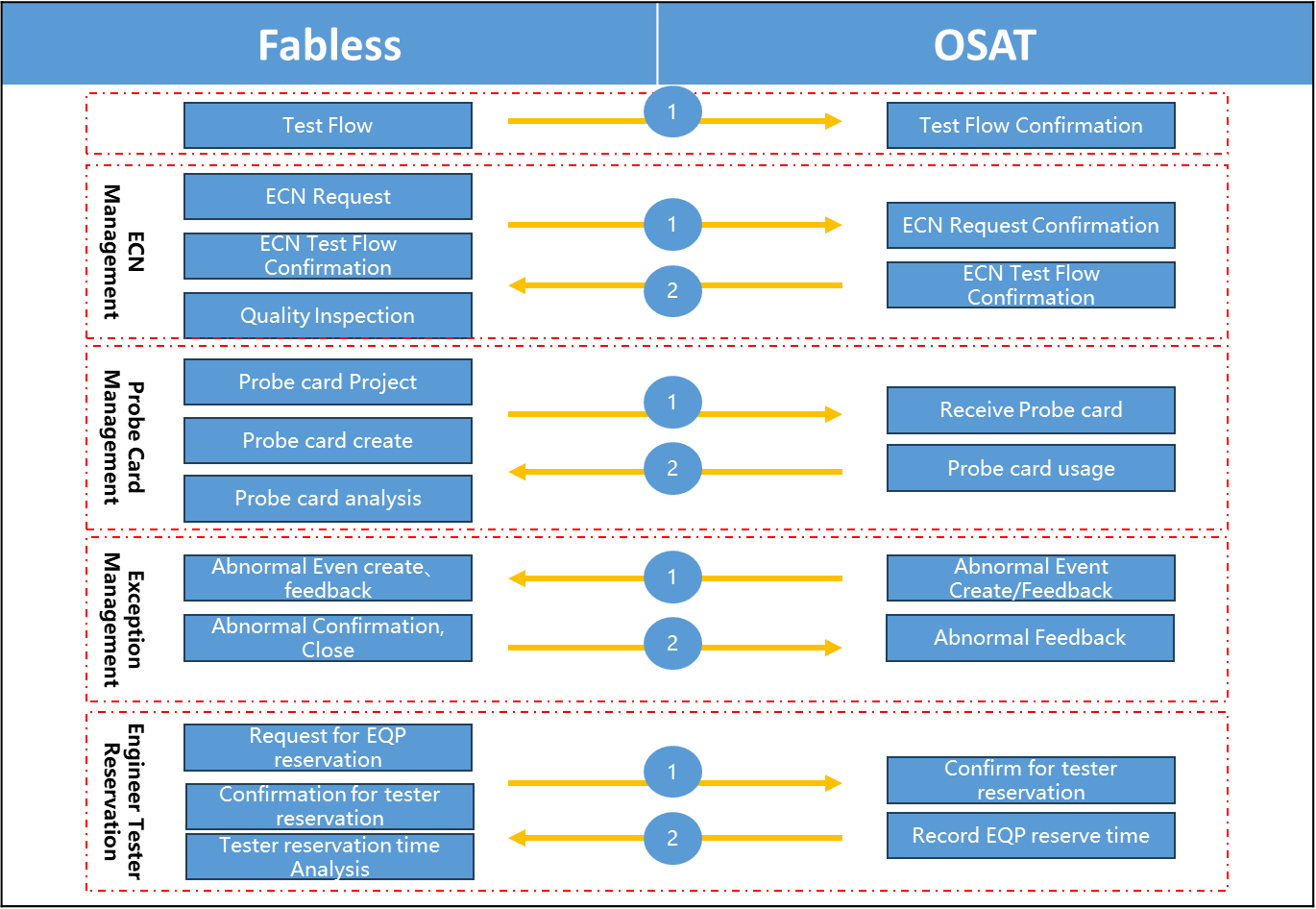

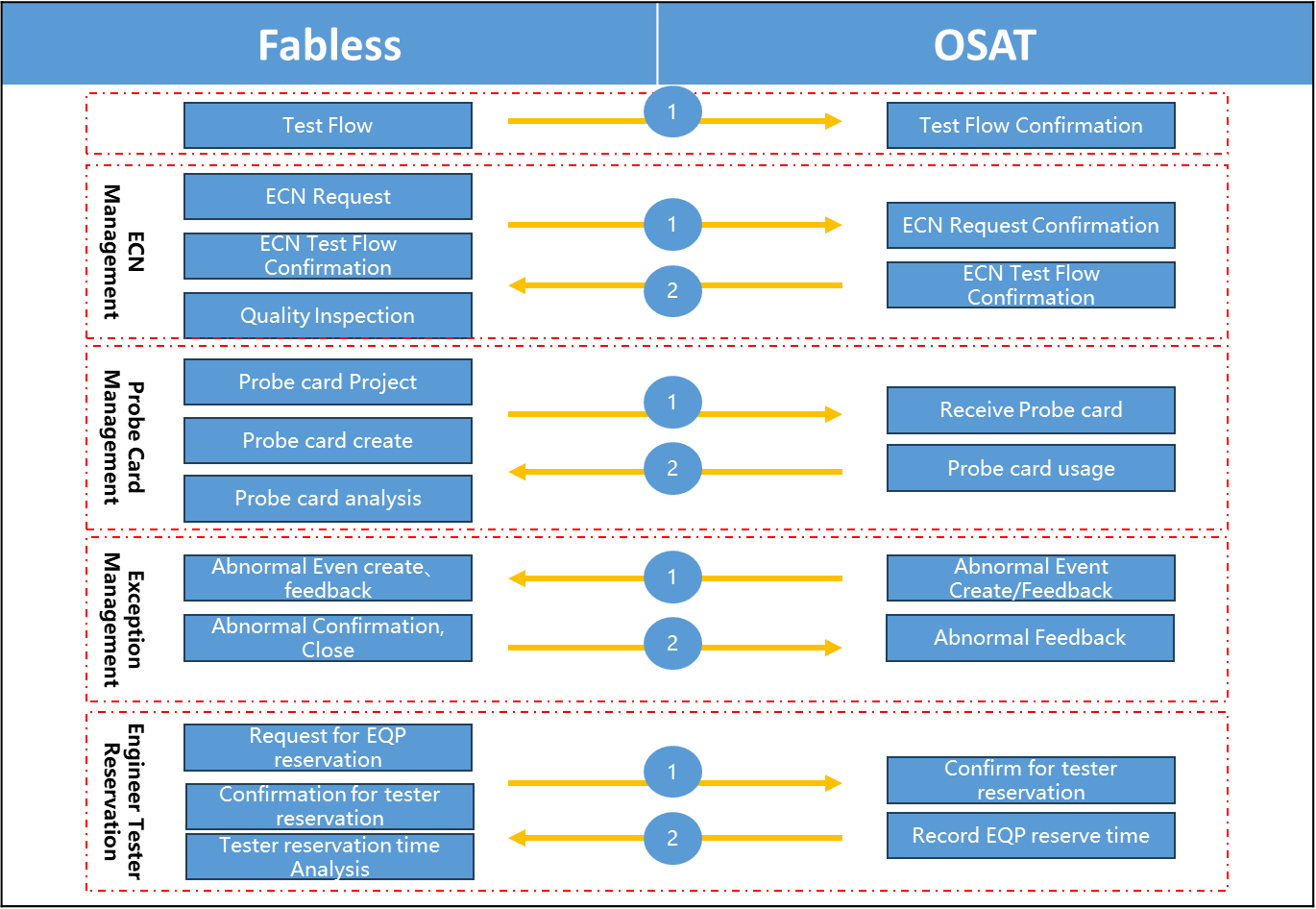

- Route & Workflow Definition: It supports the definition of product manufacturing routes and test program configurations, governed by structured, cross-functional approval workflows.

- Coordination & Dispatch: The system coordinates with Fabs and OSATs to confirm and version-control standardized product routes before dispatching work orders.

- Real-Time Monitoring & Validation: As manufacturing proceeds, SCH monitors WIP and ingests test data, performing validation checks to ensure data integrity and process compliance. It automatically flags abnormalities and initiates hold actions.

- Analytics & Improvement: Integration with Exensio provides advanced analytics, while ECR/ECN workflows ensure that process changes are managed, approved, and integrated into the knowledge base.

Benefits for Your Organization

SCH delivers measurable benefits designed to align both strategic initiatives and technical requirements.

For Executive and Management Teams:

*based on early customer deployments

- Improve Operational Efficiency: Achieve over 35% improvement in OSAT communication efficiency and more than 40% gain in product controller management efficiency. Automation of workflow processes reduces manual communication, driving consistent supplier collaboration.

- Reduce Cycle Times: Shorten new product introduction (NPI) and manufacturing/test cycle times through standardized, automated data exchanges and real-time tracking. Customers have reported faster delivery turnaround and up to 50% reduction in time to process exceptions.

- Enable AI-Driven Insights: Centralize all communication, workflows, and decisions as structured semantic data, establishing a foundation for predictive analytics and intelligent, data-driven decision-making.

- Enhance Financial & Business Integration: ERP integration provides real-time synchronization of material consumption and work orders, eliminating delays and frequent cost errors associated with manual or disconnected processes.

For Technical and Engineering Teams:

- Minimize Errors & Deviations: Automated, version-controlled product routes—sourced from PLM, reduce risk of OSAT mis-operations and enforce compliance with change requests. Real-time exception handling automates hold and expedite actions, minimizing manual oversight and rework.

- Accelerate Issue Resolution: Quality issue processing time is cut by more than 50% due to real-time, rule-based data validation and alarm management. Technical staff benefit from unified visibility into WIP and exception management for rapid response.

- Automate Data Validation and Quality Tracking: Configure baseline criteria and rule checks for automatic validation of incoming test data from factories and OSATs. SCH supports real-time quality monitoring, removing manual, siloed quality checks and ensuring procedural alignment across the supply chain.

- Build a Centralized Knowledge Base: Structured management of ECR/ECN workflows keeps product and route data current, enforces version control, and continually enriches the knowledge repository—turning each change into a documented, traceable asset.

Differentiators

SCH is engineered specifically for the complexities of the fabless model.

- Born for Fabless Operations: Unlike generic communication /collaboration solutions, SCH is an out-of-the-box unified platform designed for the specific interactive mechanisms required between fabless departments (Operations, Engineering) and external partners (Fabs, OSATs).

- Deep Enterprise System Collaboration: SCH achieves true manufacturing synergy. It integrates with ERP for financial process alignment, PLM for route standardization, and Exensio YMS to leverage advanced data analysis and create a closed-loop management system for WIP, quality, and yield.

- Structured Knowledge Base: The platform systematically captures process definitions and changes. By integrating with PLM and quality systems, it provides a robust review, approval, and version control mechanism for manufacturing routes, turning process evolution into a documented, reusable asset.

Unlock the Potential of Your Fabless Supply Chain

Take the next step toward a fully integrated and intelligent manufacturing operation. Centralize control, enhance collaboration, and build the foundation for AI-powered continuous improvement.

SCH enables AI-powered intelligence by transforming supply chain data into actionable insights. SCH provides this foundation by integrating manufacturing data and business workflows, ensuring traceability and semantic understanding.